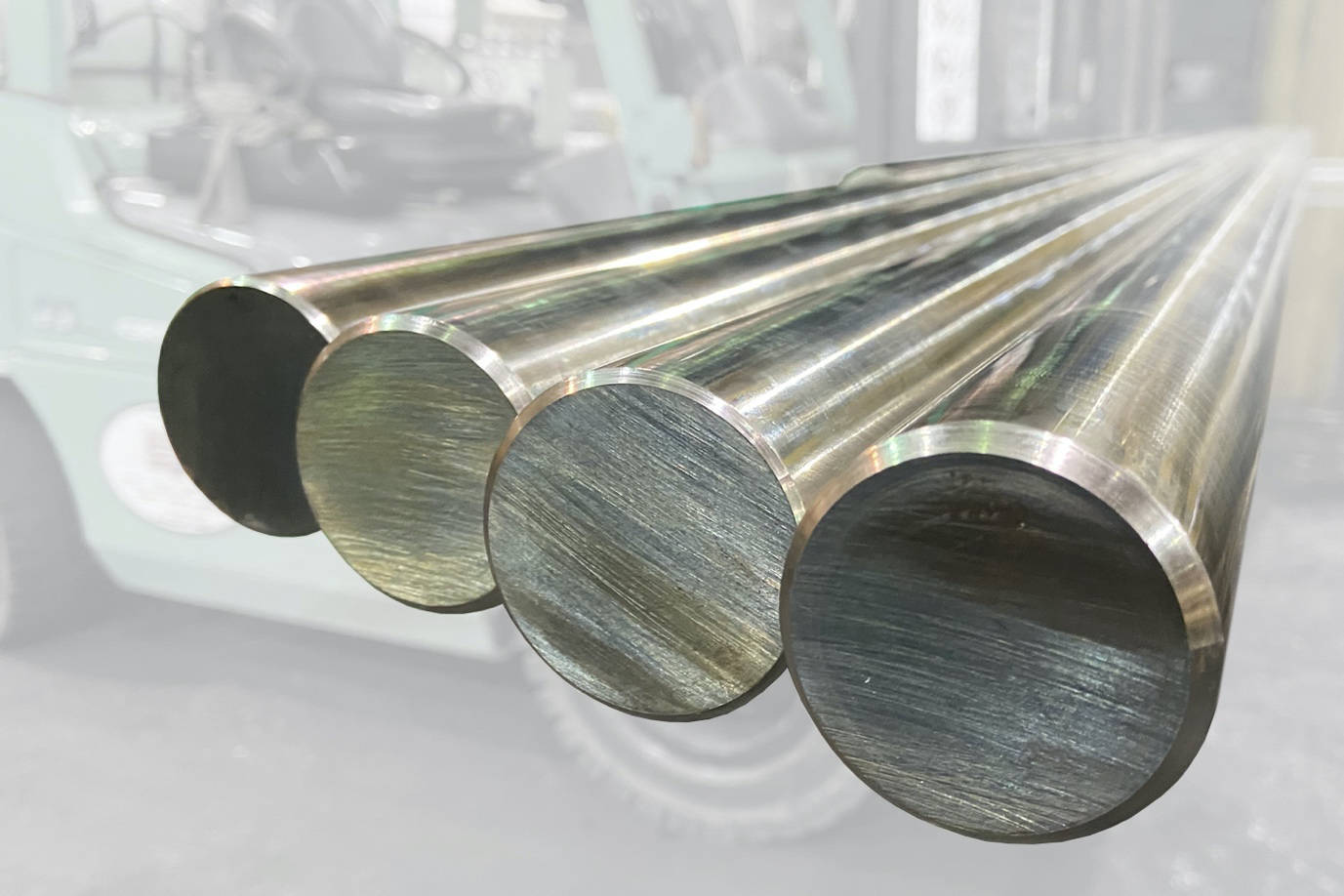

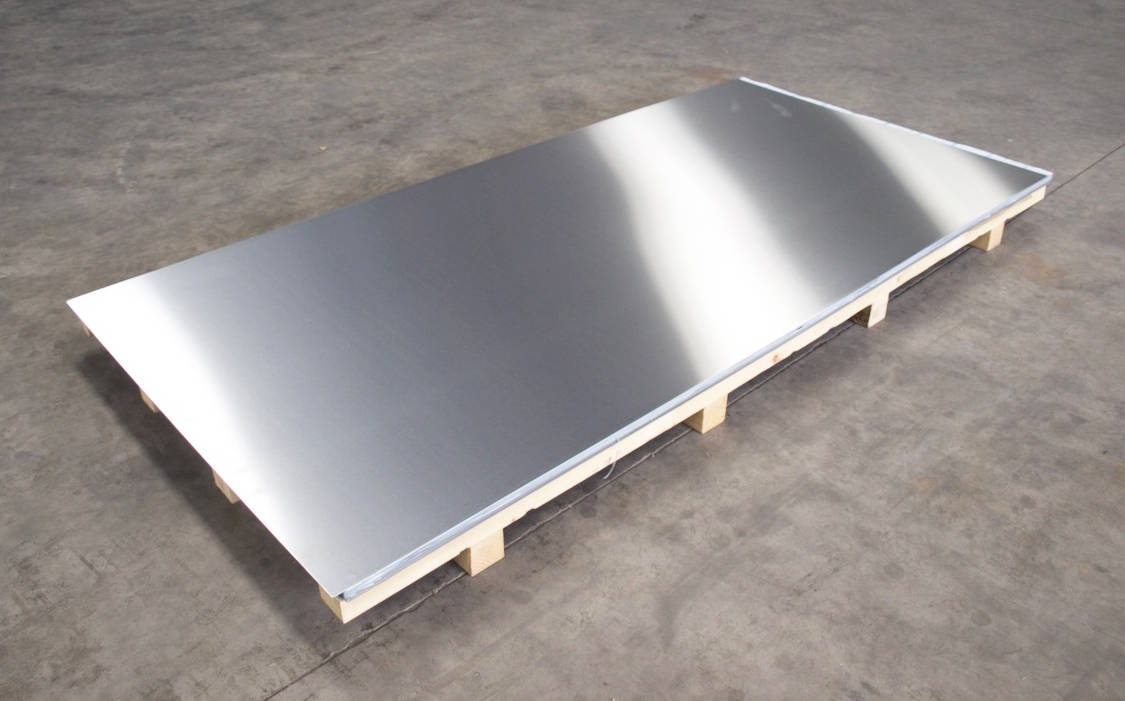

We hold a large range of Nilo® Alloy 41 stock in bars from 2inch right up to 10inch for immediate international dispatch. We also supply Nilo® 41 in plate & sheet. Where required we offer a cutting and drilling service to supply you with material to your specification and requirements. We have no minimum order requirement on Alloy 41 orders. All our metal is European produced material.

Beneficial Properties of Nilo 41

Durability: Very strong performance and toughness

Dimensional Stability: -1000C and 2600C

Flexibility: Easy to Machine. Very good weldability and workability

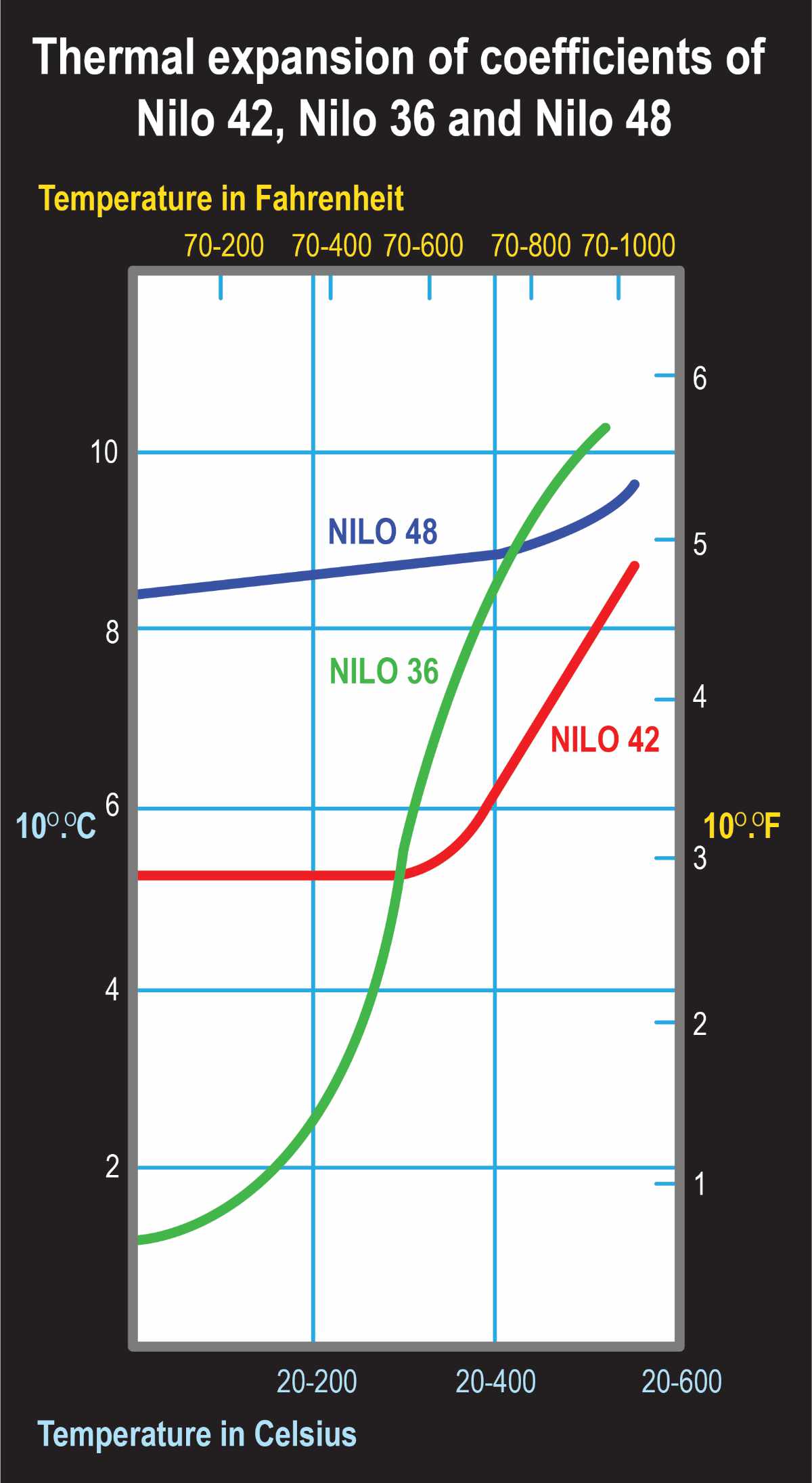

Near Zero: Coefficient of linear thermal expansion